Savings at the Gate: Jetway Extension and Optimized Boarding Strategy Promise to Reduce Boarding Times for Airlines

A unique two-door commercial aircraft boarding and deplaning proposal and a future jet bridge extension, designed and patented by Embry-Riddle Aeronautical University student Dynamite Obinna, are getting the attention of the airline industry.

The research supporting the proposal earned Best Presentation at the 56th annual symposium of the Airline Group of the International Federation of Operational Research Societies (AGIFORS) held in October 2016 in Santiago, Chile. The honor was voted on by industry members attending the symposium.

"They loved it, especially the United States’ airline representatives,” says Massoud Bazargan, professor and associate dean for research at Embry-Riddle’s Daytona Beach Campus College of Business.

The U.S. hub-and-spoke air transportation system makes time spent boarding and deplaning crucial, particularly for passengers who have tight connections to other flights. “On average, every minute of delay at an airport translates into $73. This is a cost to the airlines and ultimately a cost to passengers,” he says. For low-cost carriers that rely on shorter turnaround times to maximize profitability, delays are even more critical.

A Simulation Approach to Aircraft Braiding Strategy – Part II, published by Bazargan, et al., in 2016, shows that narrow body aircraft could reduce their gate times by up to 12 minutes by combining Bazargan’s optimized boarding strategy (the Efficient Model, first proposed in 2005) with Obinna’s jetway extension, which would use both the forward and aft doors of an aircraft for boarding and deplaning.

AirTran adopted the Efficient Model for its boarding process in 2005, saving the airline an average of 4 minutes at the gate, Bazargan says. The aircraft boarding strategy stopped working when airlines started charging passengers for checked baggage. “People started bringing more bags on the airplane, which eliminated the time savings,” Bazargan explains. However, with Obinna’s two-door boarding plan, the Efficient Model is again viable.

“When you’re operating five to seven flights a day, you need to have a maximum 25- to 30-minute turnaround time. With one door, that’s almost impossible. With two doors, the research shows it’s feasible,” Bazargan says.

A BRIDGE TO SUCCESS

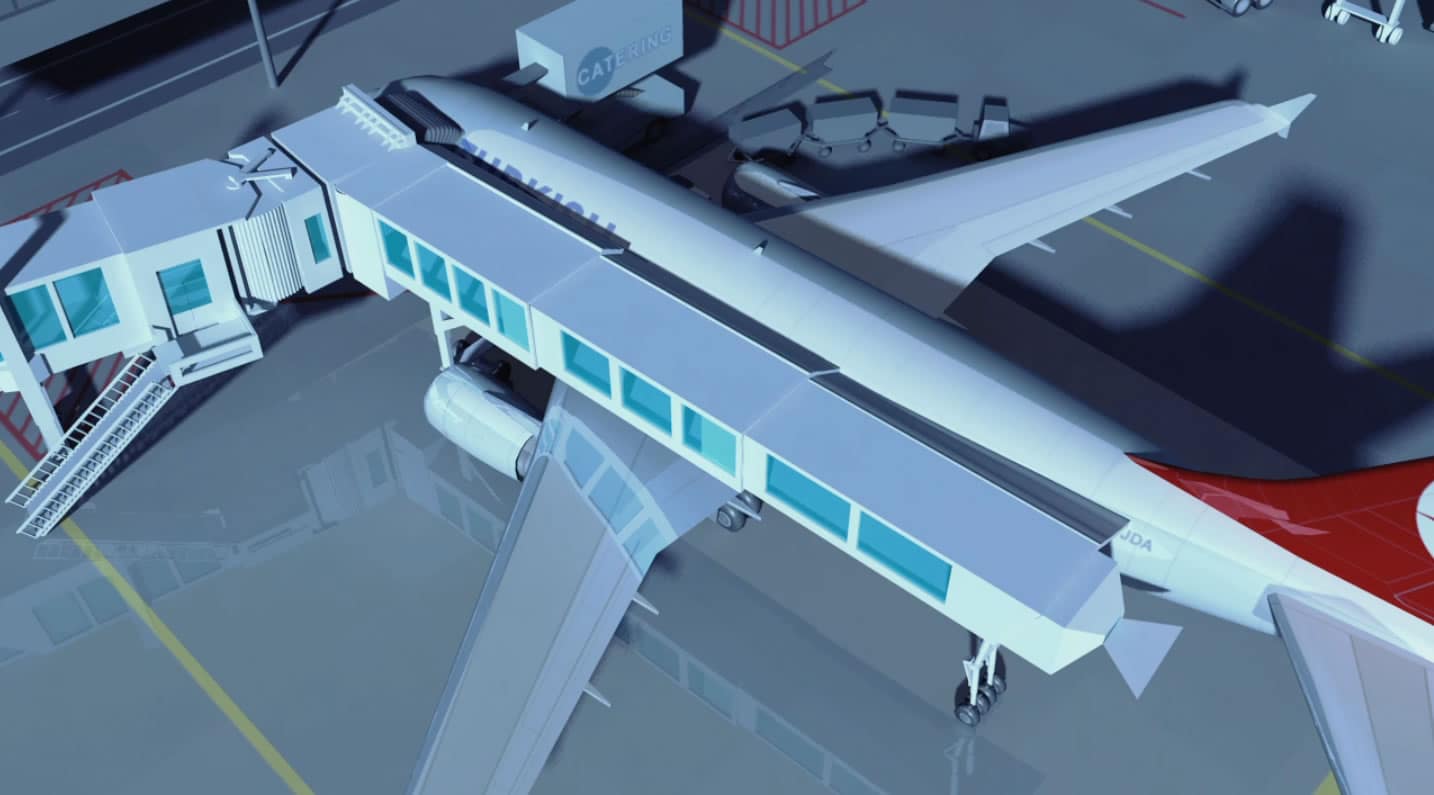

Obinna, who immigrated to the United States from Nigeria in 2010, designed the jetway extension, named the Dynaerobridge, after being frustrated with the slow deplaning process as a frequent flyer. “It was aproblem I wanted to fix,” he says.

To save space on the ramp, Obinna designed the Dynaerobridge to function as an attachment to the existing passenger jet bridges used at airports. “This is one passenger boarding bridge that replaces the need of having two,” he says. The recipient of a National Science Foundation Innovation and Research (I-Corp) grant, Obinna recently formed his own company, SkyGenex Incorporated, and is exploring possible partnerships with a jetway manufacturer or airport.

“As long as the airlines can prove a cost savings, the benefits [of the Dynaerobridge] would outweigh the initial production costs,” says Obinna, who plans to graduate in May with a B.S. in Aeronautics.

Sara Withrow

Sara Withrow