Embry-Riddle Student Teams Test Tools in NASA’s Giant Pool

When a NASA diver carried an Embry-Riddle Aeronautical University student team’s engineering device into Johnson Space Center’s Neutral Buoyancy Laboratory, the moment was 10 months in the making.

“We created 13 distinct prototypes,” Aidan Magann, Team SEAM lead and senior Mechanical Engineering student, said of the run-up to the testing session. “It was an amazing experience.”

Two Embry-Riddle squads were among 17 universities and 18 total teams selected for the final phase of NASA’s Micro-g NExT Competition, which called on the undergraduates to create, build and then test a solution to one of three space exploration challenges provided by NASA.

In June, the 18 teams traveled to Houston, Texas to test their designs in the Neutral Buoyancy Laboratory’s pool. The vast swimming pool facility provides an atmosphere resembling zero gravity, or weightlessness, and is where astronauts train for spacewalks.

Team SEAM, short for Softgoods Element Attachment Mechanism, took on the challenge of designing a tool capable of attaching two layers of soft goods during extravehicular activity at the International Space Station. Soft goods — components made from sewn or woven fabrics — are used to protect sensitive equipment from extreme temperatures in space.

“One layer of soft goods is free-floating, and one layer is already fixed and installed on the spacecraft,” Magann explained.

For the team, the trick was to make a device that worked while only having access to the front side of the soft goods. The team brainstormed for weeks, drawing inspiration from cable tie guns, drywall anchors and zip ties. Finally, they 3D-printed a tool capable of puncturing both soft goods layers with a sharp bolt.

“Once the bolt is through both layers, the operator pulls the trigger, which pulls the bolt backwards,” Magann said.

Fins on the bolt deform on the back side of the layers, while a cap on the bolt tightens. The result is a permanent connection point.

Once at the NASA pool, the tool and the team faced difficulties. At one point, the team’s fixed layer of soft goods became disconnected from the test rig, and a knob on the device’s magazine later broke off. But the team persevered, Magann said, thanks to their preparation and strong communication.

That preparation included a rigorous design process and the opportunity to work alongside NASA engineers to refine their prototype.

“We had designed the device to be fully safe and functional in the event of an accident like this,” Magann said. “Our team talked it out, and after that obstacle, our device was successful. We attached two layers of soft goods while the diver only had access to the front side, so we were incredibly happy and proud of ourselves.”

Both Embry-Riddle squads were also supported by the Microgravity Club student organization, which provided funding and additional mentorship from club administrators and previous winning team members.

“Throughout this 10-month project, we gained real, valuable, hands-on engineering experience,” Magann added.

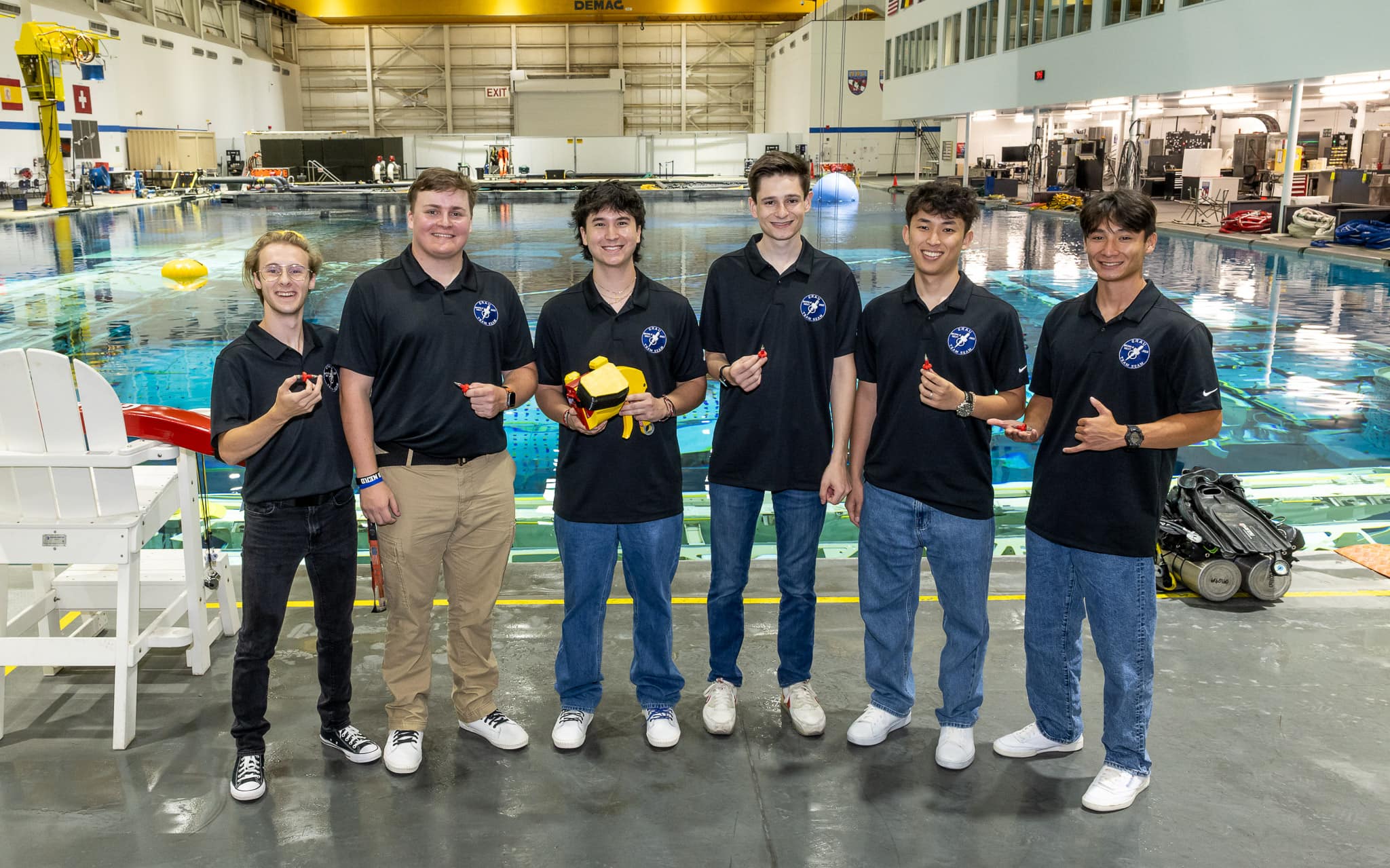

Team SEAM poses with their soft goods solution at Neutral Buoyancy Laboratory in Houston, Texas. (Photo: Embry-Riddle/Bill Stafford)

Microgravity Excellence and Innovation

Team Semaphites, the university’s second squad, chose to develop a portable radio system for use with the Orion capsule, which will transport astronauts to the moon. The system addressed a key challenge: the lack of real-time information that post-landing crews receive when approaching Orion and when out of communications range of their recovery coworkers. Their solution was designed to detect, decode and log emergency distress signals from the spacecraft.

The team’s system relied on two external antennas mounted on a tripod, said team lead Liam Stewart, a junior Mechanical Engineering major. The data was processed with custom software to produce real-time visual alerts and files for later analysis.

“Our design emphasized portability, simplicity and field-readiness, enhancing situational awareness and efficiency for recovery teams in remote or aquatic environments,” Stewart said.

For Stewart, the Micro-g NExT challenge offered valuable insight into the mechanics of engineering product research and development.

“The most important takeaway in my opinion is the process itself, sowing a real sense of accomplishment and capability once completed,” he said.

“Being onsite at a NASA facility and working with the people there was also surreal,” he added.

Dr. Sathya Gangadharan, who advised both student groups, founded the Microgravity Club more than 25 years ago and has watched Embry-Riddle’s reputation for microgravity excellence flourish.

“I am very proud to say that Embry-Riddle has evolved over the years and has acquired a very strong national recognition as a student-focused and project-oriented university in microgravity,” he said.

A professor of Mechanical Engineering, Gangadharan has, over the years, applied his experiences as a NASA summer faculty fellow at the Kennedy Space Center to launch multiple, hands-on student projects in microgravity. This includes experiments in the Johnson Space Center’s reduced-gravity aircraft.

Now, Gangadharan said, the Microgravity Club “submits about 10 detailed project proposals for the NASA Micro-G NExT student challenges” each year — a legacy of microgravity excellence and innovation they intend to continue during the 2025-26 academic year.

While in Houston, Magann was joined by teammates Nicholas Coy, Tyler Griscom, Kamanakai Natividad, Sena Nitta and Alex Ptak. Stewart was joined by Christian Aguillon, Dominic Greives, Rebecca Jeffery and Ian Mathew. Students who are interested in participating in the 2026 Micro-g NExT Competition should contact the Microgravity Club for more information.