Eagles Embrace Hands-On Learning in Air Force Research Lab Collaboration

In a collaboration with the U.S. Air Force Research Lab (AFRL) Munitions Directorate, Embry-Riddle Aeronautical University is advancing wireless radar technology, improving U.S. military capabilities and providing specialized professional training to students on a real-world project.

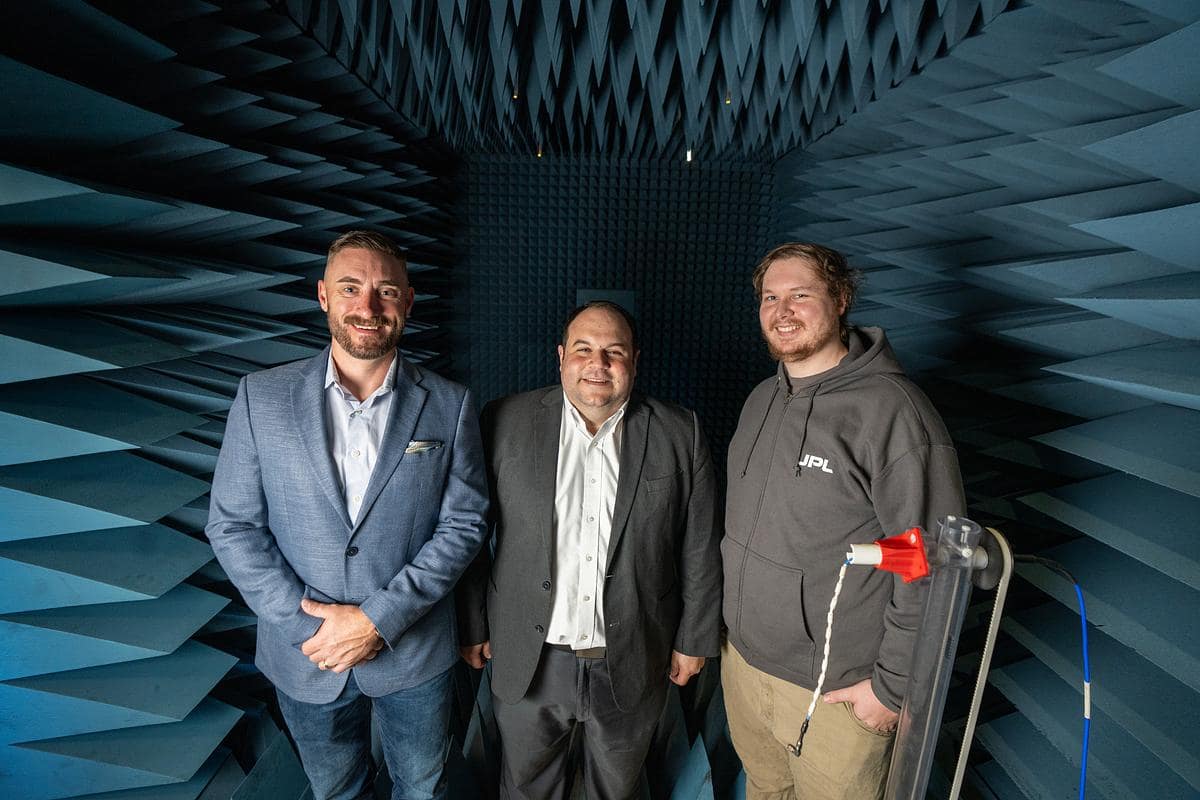

“We highly value our collaboration with the Air Force Research Lab,” said Dr. Eduardo Rojas-Nastrucci, associate professor and director of the Wireless Devices and Electromagnetics (WiDE) Laboratory in Embry-Riddle’s Department of Electrical Engineering and Computer Science. “We not only directly contribute to our nation’s interest by advancing wireless technologies, but we also create a high, long-term impact by the professionals we educate who later join the nation’s workforce.”

Dr. Amanda Schrand, AFRL senior engineer and group leader of the Resilient Hybrid Additive Development Lab, said the collaboration has “enabled Embry-Riddle to grow their exposure, network and contribute to solving very challenging technical issues.”

Schrand said the AFRL funded Rojas-Nastrucci and his WiDE lab as the primary academic collaborator on projects beginning in 2018, with continued funding expected through 2026. She and Rojas-Nastrucci coordinated between 2018 and 2022 on “innovative pipeline technology sprints” sponsored by AFRL headquarters, which were designed to quickly define and solve technology challenges related to the collaborative research projects over the course of two or three days. Representatives from other leading military, industry and academic research organizations also participated.

The sprints, and the research in general, focuses on the process of designing and producing “survivable proof-of-concept 3D-printed electronics,” that can be successfully integrated with traditional components and can withstand extreme temperatures, high g-forces, corrosion and vibration, Schrand said.

Blake Roberts, an Embry-Riddle Ph.D. student in Electrical Engineering and Computer Science, began working on the AFRL collaboration in 2019, after having become interested in Rojas-Nastrucci’s research in additive manufacturing, which is the technical term for 3D printing, and its application in military guidance systems.

“In the simplest terms, the goal is to improve the performance and capabilities of fuzing systems,” said Roberts, who is the collaboration's student lead.

In one project, the Embry-Riddle student researchers printed an antenna with conducting ink directly on the radome, which is the structure that houses and protects a radar system. By doing so, space is freed up within the housing of the radar sensors, which means for one thing that more sensors can be added to improve accuracy and performance. A continuation of the project is focused on printing a structure on the radome that can increase the success of fuzing systems.

“Additive manufacturing technologies for wireless systems are enabling unprecedented capabilities with enhanced size, weight and power, for different military payloads,” Rojas-Nastrucci said. “Embry-Riddle partners with AFRL on the discovery and development of new design techniques and manufacturing processes to advance our nation’s capabilities.”

Benefits to Students

Ryan Clayton, a Marine who earned the rank of sergeant (E-5) before leaving the military in 2017, and then earned his bachelor's and master’s degrees at Embry-Riddle while working on the AFRL collaborations, secured a job as a senior research engineer at Pratt & Whitney. His job, he said, is to use different tools and hardware testing application to assess the effect that a radar system has on an object or target.

He added that his involvement in the AFRL collaboration at Embry-Riddle was integral to his hiring.

“The work that I carried out with AFRL was an experience that most definitely helped me in getting the job that I have now with Pratt & Whitney Military Engines. Research work like that gives students a better fundamental understanding of how to implement the design, manufacturing and testing of radio-frequency (RF)-related systems and devices. In addition to that, my work with the WiDE Lab continued to feed my interest and curiosity of RF-related systems and how I could pursue that as a career path.”

Students who are interested in connecting with the AFRL can get more information about the AFRL Scholars summer program. Ph.D. students interested in applying for a post doc position to research additive manufacturing of multifunctional materials in Dr. Schrand’s lab should click here.

Michaela Jarvis

Michaela Jarvis