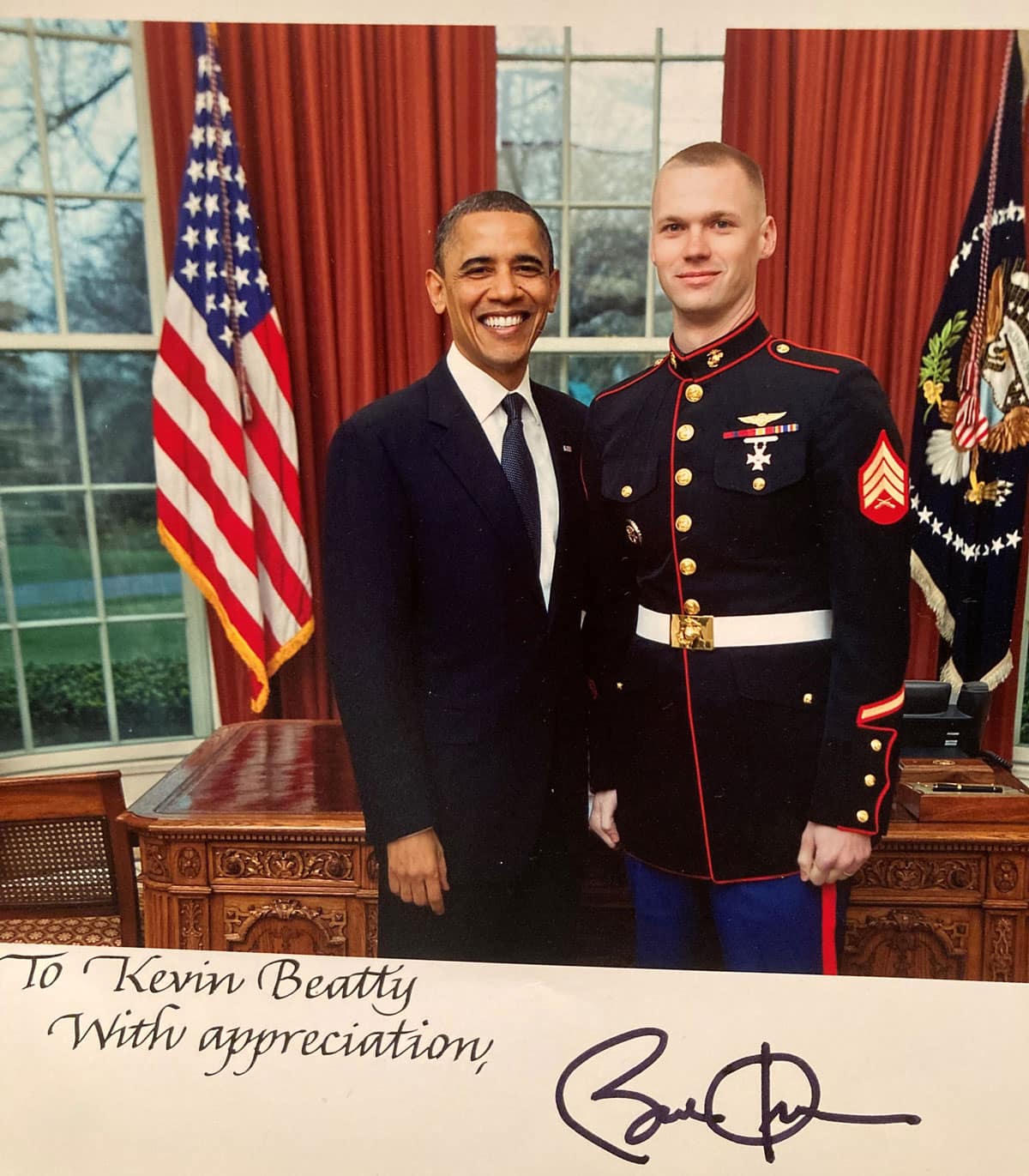

College of Aviation Spotlight: Kevin Beatty

Kevin Beatty is an accomplished Aviation Maintenance instructor at Embry-Riddle Aeronautical University. He earned a Master of Business Administration from Webster University and a Bachelor of Arts in Organizational Management from Ashford University.

Kevin Beatty is an accomplished Aviation Maintenance instructor at Embry-Riddle Aeronautical University. He earned a Master of Business Administration from Webster University and a Bachelor of Arts in Organizational Management from Ashford University.

In addition to his instructional role, Kevin has served as an acquisition analyst, providing crucial government support for the comprehensive design, development and deployment of the Presidential Helicopter training system. During the five years he served in the United States Marine Corps, Kevin logged more than 900 flight hours, with a significant portion dedicated to crewing the Marine One helicopter on more than 40 executive lifts for presidential terms that included President Obama and then Vice President Biden. Beyond his aircrew role, Kevin took on a leadership role overseeing the maintenance efforts of a team of 30+ Marines in the Flightline Work Center, serving as both a collateral duty inspector and Naval Air Training and Operating Procedures Standardization instructor.

In his free time, Kevin enjoys skateboarding with his sons, deep-sea fishing and spending as much time at the beach as possible. He also enjoys working on boats, having completed the design and installation of a marine electrical system in a commercial fishing boat. He is involved at his local church, working with and teaching middle school students every week.

Q & A with Kevin Beatty

How has your background with the United States Marine Corps influenced your approach to teaching?

I have been in the same shoes as most of my students. I started out as an E-1, like most of them, and worked my way up in my career. Coming from the same background as students helps me to be more empathetic and understanding of the struggles they face when it comes to learning new material. With that in mind, I enjoy breaking complex subjects down into simpler concepts that are more understandable to students who have little to no college experience. I know that it is difficult to learn from someone who you do not relate to, so I make every effort to get to know the students on a personal level so they know that they can trust me and that I have only their best interests at heart.

Serving as the Marine One Crew Chief, you completed over 40 executive lifts of the president. Can you share a particularly challenging or memorable experience from your time in this role?

The most memorable part was definitely my first lift. We flew through Washington, D.C., lower than the rooftops, and then landed at the White House on the South Lawn. I watched as the president came out of the house and walked right up to me and saluted. Not many people ever see the president in real life, let alone get saluted by him and then go fly with him. Despite the many emotions, I had to maintain military bearing so I couldn’t react outwardly. It was very surreal and incredibly nerve-racking knowing that there were hundreds of photos being taken and cameras recording my every move, so any slip-up would most certainly come back to haunt me, but fortunately, I never embarrassed myself too much. We trained for that moment so many times that it became muscle memory once it was showtime.

There was no room for errors or mistakes, so we rehearsed every single minute of every mission as if it were our first time. We planned every aspect, from how many seconds we would pause between movements to contingency plans should an external threat emerge. I flew with the most powerful person in the world, so perfection was not an expectation, it was a requirement. This led to an unwavering 100% success rate. This does not mean that every mission went exactly as planned. A high-profile mission in an unpredictable environment meant that every member of the crew had to be adaptable and quick-thinking. There were several instances where something would break at the last minute so performing maintenance in dress blues was common. We also spent more hours than I care to admit cleaning every inch of that aircraft. It’s as clean behind the panels as it is on the outside.

In overseeing the maintenance efforts and conducting training for Marines, what leadership lessons have you learned, and how do you inspire and motivate your team to excel in their roles, especially in critical and high-pressure situations?

Anybody in the military knows the dangers of complacency. We can get bored, distracted or arrogant, and that leads to mistakes. Every person working in the aviation industry has a significant role so the team must be able to rely on each other. I learned early on that it’s easy to forget how important each person’s role is. Our jobs must be performed perfectly every time - or we fix it - because our work affects more than just ourselves. There’s a camaraderie in the Marines that motivates you to execute at a higher degree so you don’t let anybody down. The person getting on the aircraft is somebody’s husband, wife, father, mother, brother, sister, son or daughter. In my role as the Marine One crew chief, I was the only person authorized to determine the airworthiness of the aircraft the boss was about to fly on. He, along with my coworkers and friends, depended on me to ensure the aircraft would get them home.

Anybody in the military knows the dangers of complacency. We can get bored, distracted or arrogant, and that leads to mistakes. Every person working in the aviation industry has a significant role so the team must be able to rely on each other. I learned early on that it’s easy to forget how important each person’s role is. Our jobs must be performed perfectly every time - or we fix it - because our work affects more than just ourselves. There’s a camaraderie in the Marines that motivates you to execute at a higher degree so you don’t let anybody down. The person getting on the aircraft is somebody’s husband, wife, father, mother, brother, sister, son or daughter. In my role as the Marine One crew chief, I was the only person authorized to determine the airworthiness of the aircraft the boss was about to fly on. He, along with my coworkers and friends, depended on me to ensure the aircraft would get them home.

People don’t make mistakes on purpose. There are many contributing factors, but I found that many of the mistakes can be attributed to a lack of understanding. It’s hard to keep doing something that seems irrelevant or unnecessary, so I tried to always point out the ‘why’ behind the ‘what.’ We’re taught to simply obey without questioning, but sometimes that’s easier said than done. I believe that once a person knows why they’re doing what they’re doing then they’re much more likely to keep doing it correctly.

How does working in the military compare to working in higher education?

My current role is easily my favorite job that I’ve had simply because of the mission. I love making connections with students and helping them through their educational journey. My next favorite job was working on brand new S-92s and S-76s for the OEM. I completed delivery inspections and flight tests on over 100 aircraft from the factory.

Kati Callahan

Kati Callahan