Affordable Exoskeleton Designed by Embry-Riddle Researchers Aims to Give Workers a Lift

A wearable robotic exoskeleton to prevent common worker injuries could be made more efficiently and affordably, thanks to work by student researchers at Embry-Riddle Aeronautical University.

“We’re developing an exoskeleton designed to achieve high performance while keeping the cost minimal, and it holds great promise for scalable, real-world industry deployment,” said Colin Ehrhardt, who earned his bachelor’s degree in Mechanical Engineering with a concentration in robotics.

“The exoskeleton will take the physical strain off of workers’ skeletons, their muscles and their joints,” as they perform a variety of movements, said Ehrhardt, who developed most of the controls setup for the device.

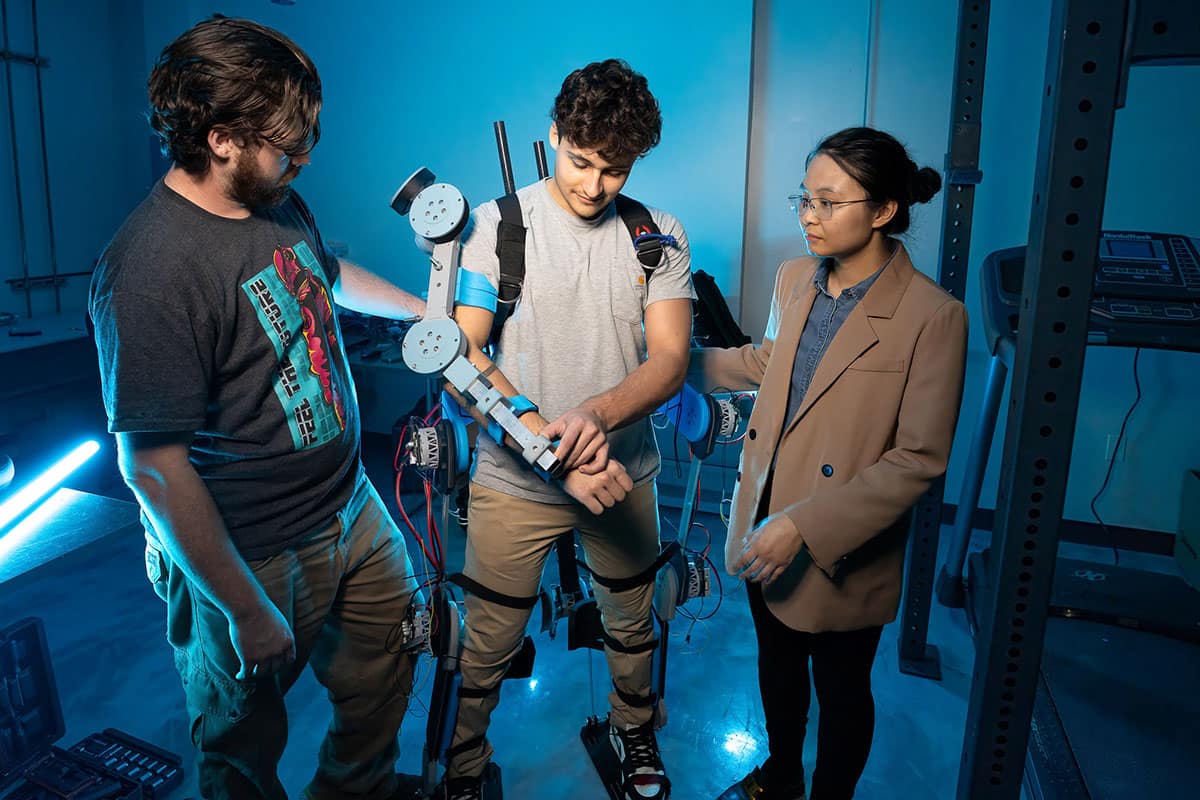

Student researchers in the Robotics and Intelligent Learning Lab and Dr. Shuzhen Luo. (Photo: Embry-Riddle/William Fredette-Huffman)

Earlier strain-reducing exoskeletons featured motors at the hip and knee with a total of eight degrees of freedom, meaning the number of ways the device can move. The Embry-Riddle team’s model introduces additional ankle control, expanding the system to ten degrees of freedom, for more natural movement.

At the same time, the new device is 3D-printed and was built using off-the-shelf components, making it significantly more affordable than comparable systems. Its modular design also allows for easy integration of additional components — such as an upper-body exoskeleton module, which the student researchers have begun developing.

The team that developed the robot — which also included Bryan Gonzalez, Marcus Targonski and Edward Aleksi — won first place in a workshop on the use of robots in construction at the 2025 IEEE International Conference on Robotics and Automation. The team was advised by Dr. Shuzhen Luo, assistant professor in the Department of Mechanical Engineering.

“It’s truly fulfilling to see our students’ innovation and dedication recognized on such a stage,” Luo said.

Dr. Patrick Currier, professor and chair of the Mechanical Engineering Department, said he was also very happy to see the students’ work recognized at a “top robotics conference,” adding that, “Dr. Luo and her students’ ground-breaking exoskeleton work has the potential to aid human performance in a wide range of difficult tasks.”

Luo’s previous research on AI-powered exoskeletonshas been published in prestigious scientific journals, including Nature.

Michaela Jarvis

Michaela Jarvis