3D Printing Could be the Key to Building Better Aircraft

Testing experimental aircraft wing designs has historically been a difficult task. Models must first be built — usually from metal, fiberglass and wood — then evaluated in a wind tunnel and, finally, iterated, making the endeavor both costly and time-consuming.

But that could all soon change, thanks to research being conducted at Embry-Riddle Aeronautical University’s Daytona Beach Campus.

In an attempt to advance the study of fluid-structure interactions, Aerospace Engineering associate professor Dr. Ali Tamijani, along with doctoral student Rossana Fernandes, a native of Angola, Africa, are pioneering the use of additive manufacturing (3D printing) to develop higher-quality and more complex aeroelastic models, which are then put to the test in Embry-Riddle’s subsonic wind tunnel.

“Aircraft structures are strong and lightweight, but they deform during flight,” said Tamijani. “We are using additive manufacturing to fabricate high-quality models with aeroelastic deformations to allow their behavior to be studied in the controlled-flow environment of the wind tunnel.”

As far back as she can remember, Fernandes has had a love for airplanes and been fascinated with space exploration, and especially the possibility of discovering intelligent life on other planets. Pursuing those fields as a career, however, almost seemed like a fantasy growing up in her home country.

“My passion led me to embrace the ambitious dream of becoming one of the first Angolan women to pursue a degree in Aerospace Engineering,” she said. “I decided to apply to Embry-Riddle because it offered the top Aerospace Engineering program.”

After graduation, she plans to work in academia for a few years before transitioning into structural engineering research and development. But for now, her focus remains on her research.

“After years of work, the most rewarding part is seeing the model being tested in the wind tunnel and fueling the interest of wind tunnel visitors,” she said. “I am eager to contribute to the next technological breakthrough. I also hope to build a career that will inspire minorities and prove that there are no boundaries other than those set by our own beliefs and mind.”

Fernandes’ work with Tamijani promises to improve the manufacturing of traditional wind tunnel models thanks to 3D printing’s ability to build objects relatively quickly, easily and — most importantly when experimenting with flexible wing designs — with varying levels of structural stiffness.

“Wind tunnel models must have the same weight and strength distribution as the actual airplane wing to accurately measure the structural and aerodynamic responses,” Tamijani said. “This approach has opened the door to experiments with a flexible wing and has elevated our design and analysis framework.”

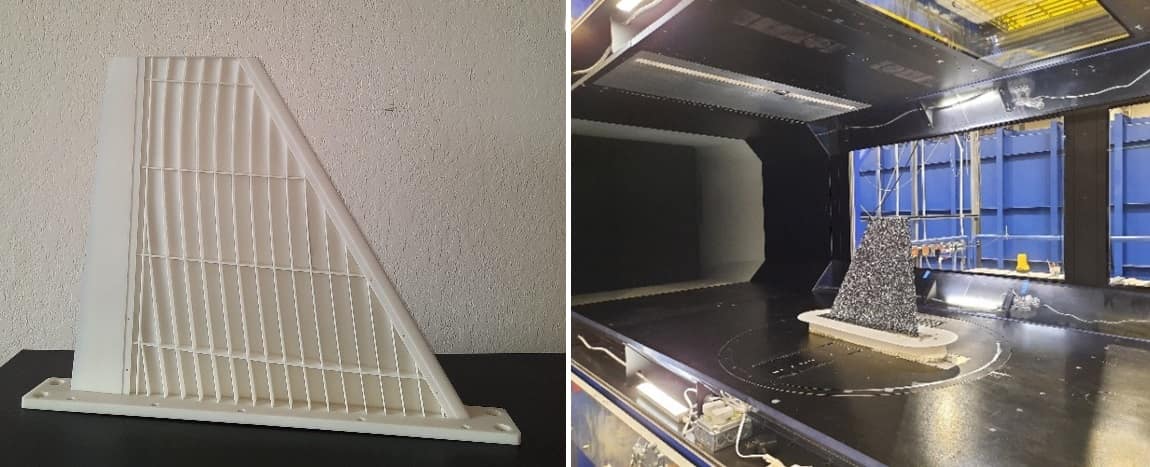

Tamijani and Fernandes recently put their research to the test with a 3D-printed generic supersonic fighter wing with a unique internal construction (see accompanying photo of the structure’s optimized interior design). Unlike conventional construction methods, additive manufacturing allowed them to test the wing with an advanced structural concept in the wind tunnel.

“By using flexible wing models with internal spars and ribs, we can more accurately reproduce the behavior of real wings in the conditions of flight,” Tamijani explained. “Therefore, we can better predict and prevent adverse aeroelastic effects or instabilities.”

The 3D-printed flexible wing was the first of its kind to be tested at the Embry-Riddle Wind Tunnel.

“It demonstrated the feasibility of 3D-printed wind tunnel models,” Tamijani said. “It also validated the prediction of the structural and aerodynamic responses from our computational aeroelastic analysis framework.”

This groundbreaking test was made possible by the computational structural mechanics expertise of Dr. Tamijani’s research group and experimental fluid mechanics expertise of the wind tunnel research faculty group composed of Dr. J. Gordon Leishman, Dr. Zheng Zhang and Dr. Ebenezer Gnanamanickam.

Next, Tamijani’s team will develop a wing designed of porous structures similar to the bones inside of a bird’s wing. This research will pave the way toward designing and testing various bionic aircraft concepts.

Mike Cavaliere

Mike Cavaliere